One thing to remember to do when rebuilding these carbs. Be absolutely sure you push a very small wire through all the circuits Especially the individual Jets and Tubes. I have written before about the nozzles having corrosion in them even when brand new. It happened to mine, and I have seen it many times in old carbs. We have had a few members who have had it happen.The idle jet nozzle is very small and long. Really a bad idea when it comes to getting clogged. If the smallest piece of corrosion or dirt is in the idle nozzle (item 5), the engine will not idle without the choke on.

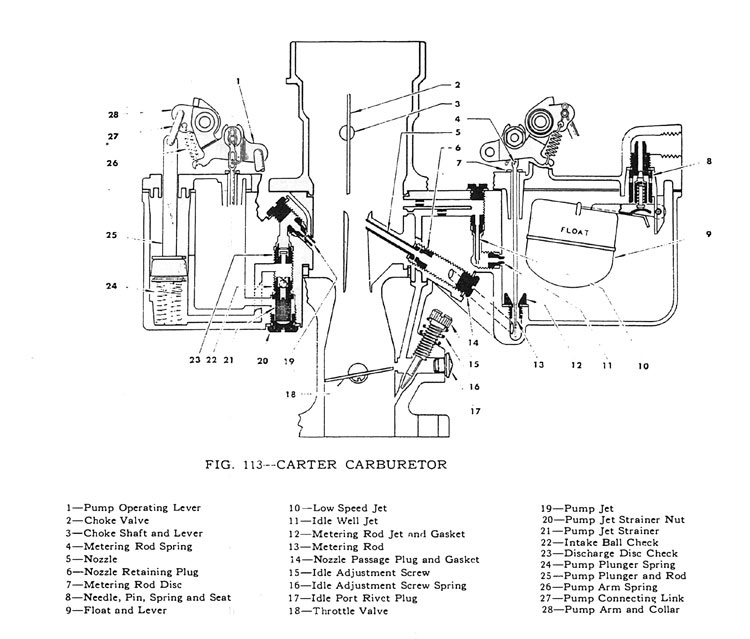

This is a WO carb, but many carb's have a similar setup.

This is a YF.

Screenshot 2024-03-29 074237.jpg

Reply With Quote

Reply With Quote